![SIS Design and Engineering [SIL Verification] SIS Design and Engineering [SIL Verification]](https://hazop.eu/wp-content/uploads/2022/09/SIS-Design-and-Engineering-SIL-Verification.png)

SIS Design and Engineering [SIL Verification]

The objective here is to design and engineer one or more SIFs and meet the integrity requirements for every SIF. This is NOT the same as Verification, however usage of the term “SIL Verification” instead of “SIS Design and Engineering” is prominent in the functional safety business.

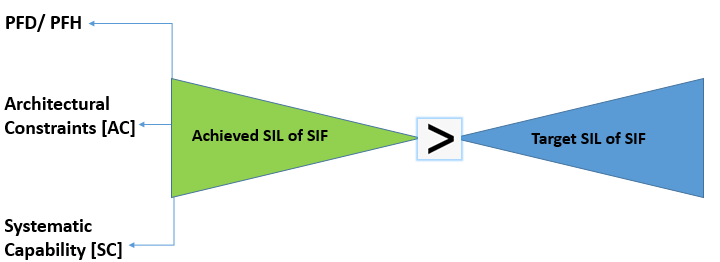

It must be ensured during SIS design and engineering that for every SIF the Achieved SIL is minimum from:

- SIL based on calculated PFDavg/PFH

- SIL based on Architectural Constraints [AC]

- SIL based on Systematic Capability [SC]

Figure: Achieved SIL Requirements

Note: The Target SIL of a SIF is known from the SIL Assessment/ Determination phase and Achieved SIL is the outcome from SIS Design and Engineering phase.

In IEC 61511-1, Clause 11, 12, 13 the requirements for SIS Design and engineering are specified. There are a number of requirements to be taken care like: separation and independence, Hardware Fault Tolerance [HFT], device selection, interfaces, systematic capabilities, failure rates, etc…

We believe in “through and detailed SIS design” and have the required expertise in design and detail engineering of simple and complex SIFs [projects ranging from 1 to 500 SIFs].

Simplified approach to SIS design and engineering

SIS design and engineering is an exhaustive exercise and requires “attention to detail and subject matter expertise”. Without having actual execution and implementation experience in designing a variety of SIFs it is practically impossible to ascertain if SIF Design is done correctly or needs rework. Just using high end software is not sufficient to claim that the Target SIL is achieved; rather one needs to know the appropriate assumptions to be used, correct source of failure rate data, etc…for a meaningful SIS Design outcome.

How can we help?

Our Functional Safety engineers are experienced professionals (certified and competent) having wealth of industry knowledge and experience not only in process/functional safety lifecycle implementation but in connecting domains like: project management, engineering design, control system integration, EPC, PMC, Site activities, etc….

During SIS design, other than using the correct failure rate data [many use optimistic data that is not applicable to the operating environment the SIFs would be used in], safety manual, etc… the biggest challenge that designers face is suggesting APPROPRIATE RECOMMENDATIONS for SIFs that do not meet the Target SIL requirements.

Our experts know how daunting it can be to actually implement and maintain recommendations like: adding an additional transmitter or an ESDV. Hence, after careful evaluation and considering practicality of the end-user/operating company site [e.g. Turnaround times, operation and maintenance team’s competency in functional safety, etc…] we suggest recommendations most suited and easily implementable like: re-looking into the SIL assessment for potential Independent Protection layer [IPLs] that were missed, adding an additional solenoid, lowering the Proof Testing Interval [PTI], evaluating possibility of partial stroke checking, etc…

To discuss how HAZOP.EU can assist your organisation regarding SIL Verification, please do not hesitate to contact HAZOP.EU for an informal, confidential conversation.