TRAINING

HAZOP, LOPA & SIL

Reducing Risks

From Design to Operation

Provisional Detailed Syllabus

Delivery Type: In-Company, Open Course Classroom, or Live Interactive Online Training.

Course Duration: Approx. sixteen (16) contact hours, which can be delivered in two (2) ways:

- Over two (2) days for face-to-face classroom training; or

- Over four (4) x half day sessions (4 hours each) for live interactive online training.

No. of Delegates: Up to 20 Delegates (Maximum) to preserve trainer-delegate interaction.

Trainer: Dr. Andrew Hallgarth, English language

Trainer: Mr. Mindaugas Ažusienis, Russian language

Important Note: Presented here is a Provisional Detailed Syllabus. This syllabus can be potentially adapted and tailored to a target industry, organisation or specific process, if required and requested by the client.

Reasons for Attending:

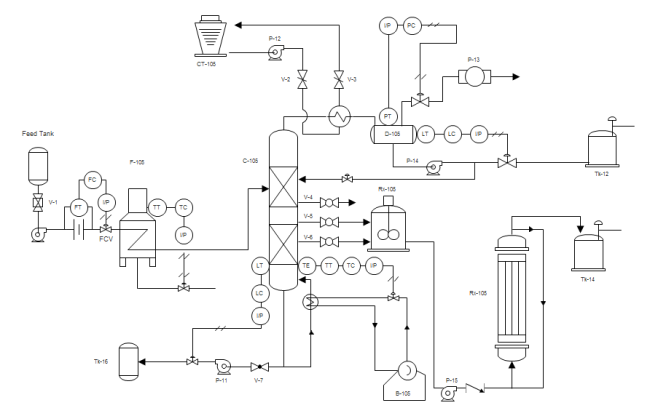

Complex processing with inherent hazards requires systematic methods for hazard identification, risk assessment and subsequently risk management. This training course has been specifically designed to introduce the importance of HAZard and OPerability (HAZOP) Studies, Layer of Protection Analysis (LOPA) and Safety Integrity Levels (SIL) in reducing process risks from design through to operational stages within a plant’s life cycle.

- HAZOP – A recognised industry-wide method of achieving a good level of hazard identification and risk assessment. HAZOP is a rigorous, structured, team-based approach to identifying process hazards and operational problems, which can be adapted to a variety of processes and technologies.

- LOPA – A semi-quantitative risk analysis method, for the protection against an untoward or serious consequential scenario by means of one or more protection or safeguard levels or layers. LOPA is used to evaluate the risk of a selected hazardous scenario by establishing an order of magnitude approximation of risk. The estimated risk is then compared with risk tolerance criteria to decide whether the existing layers of protection are adequate or if additional risk reduction or layers are required.

- SIL – The assignment of a SIL value addresses the need to provide safeguard, mitigation or protection layers matching the potential hazards of the processes, including the failure of the instrumented systems. SIL is a measure of the reliability of the respective Safety Instrumented System (SIS) that has a Safety Instrumented Function (SIF).

This course will not only help delegates to understand and be aware of the purpose of HAZOPs, LOPAs and SILs, but how each type of study can be used to reduce risks in the process or plant’s lifecycle from design to operational stages.

Key Benefits of Attending:

- GAIN KNOWLEDGE about Process Safety and HAZOP, LOPA & SIL methodologies and associated studies.

- DISCOVER & LEARN when and how HAZOP, LOPA & SIL studies should be employed in relation the process or plant’s lifecycle between design and operational stages.

- IMPLEMENT & OPTIMISE HAZOP, LOPA and SIL studies as an integral part of your organisation’s risk management system at different lifecycle stages.

- ADOPT effective control measures to eliminate or minimise significant risks using HAZOPs, LOPAs and SIL methodologies.

- SUPERCHARGE your own understanding and development of Process Safety and HAZOP, LOPA and SIL methodologies whilst benefiting your organisations’ safety and operational knowledge base.

Who Should Attend and Target Industries?

This training course is suitable to anyone who has a responsibility relating to management, operation, commissioning, design, maintenance which would have a health, safety and environmental, financial and business impact. Typical people who should attend this course include, but not limited, to:

- HSE, Plant & Facility Managers and Engineers.

- Process Engineers and Chemists.

- Maintenance & Commissioning Managers and Engineers.

- Instrumentation, Electrical and Mechanical Engineers.

- Designer, Project, Planners Managers and Engineers.

- Loss Prevention & Risk Management Processionals.

- Emergency Planning & Major Incident Investigation Personnel.

- Regulatory Personnel.

This training course will be specifically interesting to people operating within, but not limited to the following industries: Oil, Gas and Petrochemical, Chemicals, Heavy & Construction Manufacturing, Food, Beverages, Pharmaceutical, Fast Moving Consumer Good (FMCG), Metal Manufacturing, Mining and Minerals, Utilities including Power Generation, Defence and Military. Other industries who have assets that have Major Accident Hazard (MAH) potential may also be interested, as well as personnel in government organisations who monitor and regulate these industries.

Training Methodology & Daily Schedule:

This two (2) day “Introduction to HAZOP, LOPA & SIL” training course will be professionally presented in discrete yet interconnecting modules using an effective interactive seminar style and multimedia presentations.

A course manual, including the presentation and accompanying notes will be distributed to all course delegates in both paper (physical training pack) and/or electronic formats (i.e. PDF).

It is anticipated that the daily schedule will follow the typical format expressed below for classroom physical face to face training, which will generate on average eight (8) hours contact time with the trainer, per training day:

08:00 – Morning coffee & registration, Course Begins at 08:30

10:30 – Morning refreshments and networking break

10.45 – Course re-commences

12:45 – Networking luncheon

13.15 – Course re-commences

15:15 – Afternoon refreshments and networking break

15:30 – Course re-commences, Course concludes at 17:30.

Alternative, if clients or delegates would require this training course delivered through the medium of live interactive online training sessions, these can be provided over the following suggested schedules, but can be tailored to suit the working pattern of the class/delegates in question. Please note that each training session will be conducted over a maximum of four (4) hours contact per day to preserve the attention span of the class/delegates. It is anticipated that these live interactive online training sessions will be conducted over four (4) consecutive days.

- Morning Session: 08:00 to 12:15, with a 15-minute break in between.

- Afternoon Session: 13:00 to 17:15, with a 15-minute break in between.

- Evening Session: 18:00 to 22:15, with a 15-minute break in between.

Certification & Feedback

Certification of achievement and attendance will be issued on the successful attendance, completion and passing the end of course assessment. ADH Risk Ltd will issue its own independent course feedback form to be completed by attendees at the end of the course for quality feedback purposes. ADH Risk Ltd will also require a copy of any other issued feedback forms, once completed by the delegates for feedback reasons.

TRAINING DAY 1: HAZOP

- Course Introduction & Administration.

At the beginning of the training course, the trainer & delegates will introduce themselves and share what they would like to gain from the course ahead. Also, basic housekeeping including training course schedule, fire alarm & evacuation procedures will be shared.

- MODULE T1: What is Process Safety and Why is it Important?

- Introduction to Process Safety, its history and development.

- What are Hazardous Events, Risks and Tolerability?

- Typical Incidents that Concern Us & Industrial Accidents of Major Significance.

-

- Process Safety Management (PSM) Drivers and Timelines.

- MODULE T2: Process Hazards & Risk Management Alternatives.

- What increases the potential for Industrial Facilities or Transportation to become more hazardous?

- How are process risks analysed?

-

- Risk vs. Safety: A Comparative View.

- Tolerability, Management and Measurement of Risk.

- MODULE T3: Hazard Identification & Risk Management from Design to Operational Stages.

- Risk Management for New (Proposed) & Existing Hazardous Facilities.

- How can HAZOP, LOPA & SIL can reduce risks in the lifecycle process.

- When and where to use HAZOP, LOPA & SIL in the process lifecycle.

- MODULE T4: HAZOP Basics.

- What did we do before HAZOPs and how do we know a plant is safe?

- HAZOP Methodology & Process Steps.

- What type of HAZOP should you use?

- Variations in HAZOP types.

- MODULE T5: HAZOP Pitfalls, Optimisation of HAZOPs & Sizing of Nodes.

- Pitfalls of HAZOPs.

- Optimisation: When to do what…

- Choosing & Sizing of Nodes for HAZOPs

- MODULE T6: HAZOP Protocols, Controls, Consequences & Safeguards.

- HAZOP Protocols.

- Administration & Engineering Controls.

- Controls as Safeguards.

- Consequences of Failures of Controls.

- END OF FIRST DAY OF TRAINING COURSE.

TRAINING DAYD 2: LOPA & SIL

- MODULE T7: Layer of Protection Analysis (LOPA).

- Introduction to LOPA.

- Scenario Development.

- Consequences & Severity Estimation.

- Initiating Events and Frequency Estimation.

- Independent Protection Layers.

- Applications of LOPA.

- MODULE T8: Safety Integrity Levels (SIL).

- Safety Life Cycle.

- SIL Assignment Methodologies.

- New and Existing Systems.

- SIL Verification.

- Important Aspects of SIL Application.

- MODULE T9: Study Revalidation & Management of Change (MoC).

- Overview, Objectives & Considerations of Study Revalidation.

- Study Revalidation Checklist of Suggested Items.

- Changes that justify studies, Implementation, Management of Recommendations.

- Management Dilemma & Presenting Recommendations.

- MODULE T10: Question & Answer Session.

- Open to discuss any aspects of the training and cover off items identified at the start of the training session, which have not been covered.

- Post-Training Course Assessment.

- END OF SECOND DAY OF TRAINING COURSE.