Functional Safety Audits

Functional Safety Audits

Why do a FS Audit and IEC 61511 requirements?

Conducting a Functional Safety Audit will help review information, documents/drawings and records to determine whether a Functional Safety Management system is in place, is up to date, and being followed. Where gaps are identified, recommendations for improvements are made.

Primary objective of a FS Audit is to ensure compliance with procedures. Auditors do not assess the adequacy of the work they are auditing and do not make specific judgments about functional safety and integrity of a SIF [which forms a part of FSA]. FS audit will not ascertain as to whether the required level of functional safety has been achieved; it only confirms that the correct procedures are being followed and implemented. Sometimes, a functional safety audit may be carried out as part of a FSA, however it shall be ensured that the objectives and requirements of the FS Audit are met.

FS Audit requirements are listed in IEC 61511-1, 5.2.6.1.

The standard says, “All procedures, identified as necessary resulting from all safety life-cycle activities shall be subject to safety audit.”

Our simplified approach to FS Auditing?

We believe in “quality auditing” and hence we are cautious about the time spent at each stage of the auditing process, like:

Audit preparation [scope, timing, etc…] and intimation of the audit dates to the customer, actually conducting the audit, reporting of the findings and audit- follow-up [if required by the customer].

We make sure that our audit process doesn’t scare the auditees and neither does it generates volumes of documentation that convey no meaning and creates difficulty in understanding and closing the audit recommendations. We focus on the overall implementation of SIS and provide realistic feedback to management about whether the procedures for functional safety are working well in practice.

To know our approach to FS Auditing, please see a sample FS Audit that was conducted during the FEED stage of a project. This was using a checklist based method.

However, if an end-user would like to apply another suitable audit approach to gain information on the effectiveness of implementation of their SIS, we can consider other types of audit activities like: Inspections, Safety Visits [e.g. plant walkthroughs, etc…The IEC Standard makes no requirements for frequency of auditing activities, however in our experience initially it can be considered once / year and as and when the team gets a good grip of the installed SIS, once every 2 years should be good.

—————————————————————————-

How can we help?

Our FS auditors are experienced engineering professionals (certified and competent) having a wealth of industry knowledge and experience not only in process/functional safety lifecycle implementation but in connecting domains like: project management, engineering design, control system integration, EPC, PMC, Site activities, etc…. They have the required auditing skills that will help ensure a quality audit is performed and appropriate recommendations are given against each audit point/ findings with relevant reference from the IEC 61511 standard.

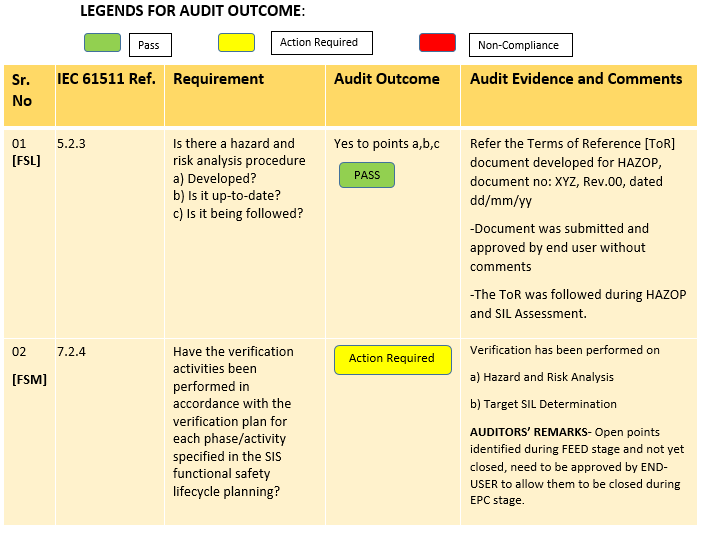

Sample from a FS Audit that was conducted for a FEED Stage Project.

The below table lists the comprehensive Audit Checklist developed for Functional Safety Management [FSM] and Functional Safety Lifecycle [FSL] phases as per IEC 61511, Part-1

FS Audit Example Tabulation

To discuss how HAZOP.EU can assist your organisation in conducting Functional safety audit, please do not hesitate to contact HAZOP.EU for an informal, confidential conversation.